Know more your ignition engine system, read this ignition component first (part 1)

Ignition System Components

A. Battery

This

component serves to provide current 12 Volt low voltage for the ignition coil.

The battery is an electrochemical made to supply power to the engine starter

system, ignition system, lights, and other components. This tool store

electrical energy in the form of chemical energy released when needed and

supply it to each of the electrical system. The charging cycle and expenditures

occur continuously.

1.

Battery

Construction

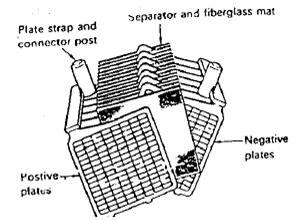

In

the sulphuric acid electrolyte batteries are the positive electrode and negative

electrode in the form of plates. The rooms are divided into several cells, and

in each - each cell there are some elements that are submerged in the

electrolyte.

a. Battery element

Inter

plates positive and negative each connected by a strap plate. Bond positive and

negative plates mounted alternately bounded by separator and fiberglass, the

preparation of this plate broad aim enlarge allusion between the active

ingredient and the electrolyte so that the electricity generated great.

b. Electrolyte

Battery

electrolyte is a sulphuric acid solution with distilled water, the density of

the electrolyte in the battery in a fully charged state is 1,260 or 1,280 (at a

temperature of 20º C). 1.260 specific gravity electrolyte containing 65%

distilled water and 35% sulphuric acid, while the electrolyte density 1.280

containing 63% water and 37% sulphuric acid.

c. Battery box

Battery

boxes are divided into six rooms or cells, in which there is a sign of upper

and lower surfaces. Elevated position from the base plate and given a baffle,

aim to prevent the short circuit.

d. Ventilation Stoppers

Stoppers

vent is close to filling hole electrolytes, aims to separate hydrogen gas out

through the ventilation holes while the sulphuric acid vapour condenses on the

edge of the vent and drip back down.

B. Ignition Switch

The ignition system ignition serves to

connect and disconnect the electric current flow from the battery to the

ignition coil.

C. Ignition Coil

In this system, the ignition coil

serves to raise the voltage (12 V) into a high-voltage (15 KV to 20 KV)

required for ignition. To enhance the low voltage of the ignition coil there

are two coils, namely;

1. Primary coils. This coil creates a

magnetic field serves the ignition coil to be raised on the coil-coil

induction. Characteristic of the primary coil is a coil that has a large cross

section and roll a little.

2. Secondary coil. This coil serves to add

an induction into a high voltage to the spark plugs were subsequently channelled

into a spark. The hallmark of the secondary coil is a coil that has a small

cross section and rolls very much. For more details, see the image below.

a.

The

workings of the ignition coil

The theory of the high voltage

The

voltage that occurs in the coil ignition coil based on the principle of mutual

induction / induction together. If on an iron bar wrapped so that it becomes a

fine wire coil, then electrified, then in the iron core magnetism will occur

with the line style.

A

magnetic force that occurs in the iron core depends on two factors, there are;

a large number of coil windings and the current flowing in the coil

if

the contact point is open, an electric current flowing from the battery to be

disconnected, but the lines of magnetic force that arises in the iron core

tends to continue the flow of electric current. The tendency lines of magnetic

force to continue the flow of electric current will cause an electric current

to the coil even if the electric current of the battery is not flowing. This

incident is said to coil induced by lines of magnetic force are lost because

only the induced coil is called induction alone

b.

Various

Ignition Coil.

On vehicles

generally use three kinds of ignition coil;

1) Canister Type

This type has an iron core in the

middle and the secondary coil surrounds the iron core. The primary coil is

located on the outer side of the secondary coil. Overall components are

assembled in a house in a metal canister. Sometimes a canister filled with oil

(lubricant) to help reduce the heat produced by the coil. Constructions type of

canister as shown in the figure below.

2) Moulded

Moulded-type coil is a type that is

now commonly used. In this type of iron core in the middle, surrounded by the

primary coil, while the secondary coil is located on the outside. Overall

assembled components are then wrapped in resin (amber) to be resistant to

vibration commonly found in motorcycles.

Moulded type of coil a popular

choice because it is resistant and robust construction. In multicylinder

engines (many cylinder) usually one coil serves two spark plugs because it has

two high voltage cables of the secondary coil.

3) The combined coil mode (fused) with cap

plugs (spark plug)

This coil mode is a type of the most

recent and often referred to as coil rod (stick coil). The large size and

weighs less than the type of moulded coil and biggest advantage is this coil

does not require a high voltage cable.

Komentar