automotive, heavy vehicle lubricant

Short description: lubricant properties and test methods

Learning outcome: students can explain the various properties possessed by the lubricant and how the testing is done

relevance: students can perform effective lubrication procedures on a heavy equipment unit

What is meant by kinematic viscosity is the average size showing the liquid rejection of the pouring of a fluid. While the general definition is condensed or diluted a fluid is measured by the flow time parameter of a fluid from point A to point A '.

Kinematic viscosity @ T ° C = t x K

Unit = cSt (centistokes) with

t = flow time,

K = pumpkin constant,

T = measurement temperature

2. Absolute viscosity

What is meant by absolute viscosity is the size of the liquid rejection of the form changes under shear stress, and the shear stress ratio with the change of velocity to the change in the thickness of the lubricant.

3. Index Viscosity

H = price of basic kinematic viscosity, at 100 ° C

U = V40: kinematic viscosity at 40 ° C (cSt)

Y = V100: kinematic viscosity at 100 ° C (cSt)

N = exponent

H = price of basic kinematic viscosity at 100 ° C

U = kinematic viscosity at 40 ° C (cSt)

Learning outcome: students can explain the various properties possessed by the lubricant and how the testing is done

relevance: students can perform effective lubrication procedures on a heavy equipment unit

Properties of Lubricants and Test Methods

ViscosityThe deficit of the viscosity is a measure of fluid rejection of the deformation under shear stress or fluid rejection of the pour. Based on the measurement, the viscosity is divided into two points of view:- Kinematic viscosity

- Absolute viscosity

What is meant by kinematic viscosity is the average size showing the liquid rejection of the pouring of a fluid. While the general definition is condensed or diluted a fluid is measured by the flow time parameter of a fluid from point A to point A '.

Kinematic viscosity @ T ° C = t x K

Unit = cSt (centistokes) with

t = flow time,

K = pumpkin constant,

T = measurement temperature

2. Absolute viscosity

What is meant by absolute viscosity is the size of the liquid rejection of the form changes under shear stress, and the shear stress ratio with the change of velocity to the change in the thickness of the lubricant.

Picture 1. absolute viscosity

The relationship between kinematic viscosity and absolute viscosity can be shown by the following diagram:

Picture 2. relationship between kinematic viscosity and absolute viscosity

What

is meant by the viscosity index is the magnitude of the number or index

showing the resilience of the viscosity change of the lubricant to the

temperature change.

If the index viscosity is large, the effect of temperature changes on the viscosity changes is low (stable). Whereas if the index viscosity index is small, then the influence of temperature changes on the viscosity changes high (labile)

The standard temperatures used to measure the viscosity index are 40 ° C and 100 ° C. lubricants having high index viscosity have not changed much. Method of calculating index viscosity based on ASTM D2270 (IP 226)

If the index viscosity is large, the effect of temperature changes on the viscosity changes is low (stable). Whereas if the index viscosity index is small, then the influence of temperature changes on the viscosity changes high (labile)

The standard temperatures used to measure the viscosity index are 40 ° C and 100 ° C. lubricants having high index viscosity have not changed much. Method of calculating index viscosity based on ASTM D2270 (IP 226)

The following graph influences the viscosity index in the lubricant

- SAE 10 more dilute than SAE 40

- SAE 50 is thicker than the SAE 40

- SAE 10W-40 is more dilute than the SAE 40 at low temperatures

- SAE 10W-40 is similarly dilute than SAE 40 at elevated temperatures

code W (winter) as an indication of viscosity at low temperatures. It means SAE 10W-40 is easier to start than SAE 40, and SAE 10W-40 means having a higher index viscosity than SAE 40.

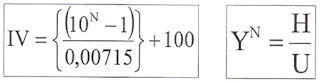

4. Determine the index viscosity

Here is the formula for calculating kinematic viscosity at 40 ° C and 100 ° C. for index viscosity <100:

L = the price of the basic kinematic viscosity, at 40 ° CHere is the formula for calculating kinematic viscosity at 40 ° C and 100 ° C. for index viscosity <100:

H = price of basic kinematic viscosity, at 100 ° C

U = V40: kinematic viscosity at 40 ° C (cSt)

while for index viscosity >100:

N = exponent

H = price of basic kinematic viscosity at 100 ° C

U = kinematic viscosity at 40 ° C (cSt)

Komentar